Complete Vehicle Manufacturing

How to start production on time and get your vehicle on the road - without using up valuable production capacity.

Over the years, 33 different models have rolled off our production lines in various quantities, making a total of more than 4 million vehicles. Our state-of-the-art facilities can accommodate vehicles with conventional, hybrid and electric powertrains, sometimes on the same production lines, providing versatility no other independent manufacturer can match. Magna manufactures complete vehicles to world-leading standards, and we do it in a sustainable factory — our production processes is carbon-neutral since 2022.

Use the links below for a quick navigation to your topic of interest:

Complete Vehicle Manufacturing

One-Stop Shop | Flexible Manufacturing | Body-in-white | Paint | Asembly

Take the 360° virtual tour for exclusive

insights into our manufacturing facilities!

Complete Vehicle Manufacturing

– a One-Stop Shop

As one of the world’s leading independent contract manufacturers, Magna is a key strategic partner for a host of global OEMs. Thanks to our comprehensive automotive expertise, flexibility, and experience of working with a wide range of OEMs, we are uniquely positioned to support traditional automakers whenever they need extra capacity, and to help New Entrants to the automotive industry get their latest products on the road.

.tmb-product@2x.webp?sfvrsn=b2761449_0)

Tailormade turnkey solutions for your vehicle

The one-stop shop allows our customers to benefit from extensive support and expertise for vehicle concept industrialization. Starting with the feasibility check of the initial concept, the definition of vehicle targets, and supplier sourcing – we have got you covered! Our engineers work in tandem with our manufacturing team to ensure precision from the design to the manufacturing. Sophisticated development and testing processes guarantee optimized production planning and a quick time-to-market.

Sustainable Factory

At Magna, sustainability is one of our key objectives. Achieving it means reducing our environmental impact at every stage of our complete vehicle manufacturing process. We are proud that our Graz plant is carbon-neutral since 2022, but we want to go even further. We see raising our employees’ awareness of the environmental impact of our business and helping them to reduce their personal carbon footprints as essential steps on the road to sustainability.

Program Management

In an industry as complex as the automotive sector, the ability to plan, manage and monitor a vast number of potentially interdependent processes is essential. Magna’s combination of project management experience and unique vehicle engineering and manufacturing expertise means we can take overall responsibility for all our projects.

Purchasing and Supply Chain Management

The combination of high complexity and huge numbers of variables can make managing automotive supply chains a challenge. We can help! Our comprehensive package includes proven, standardized processes and a wide, reliable network of international suppliers and partners, as well as all our years of experience and expertise.

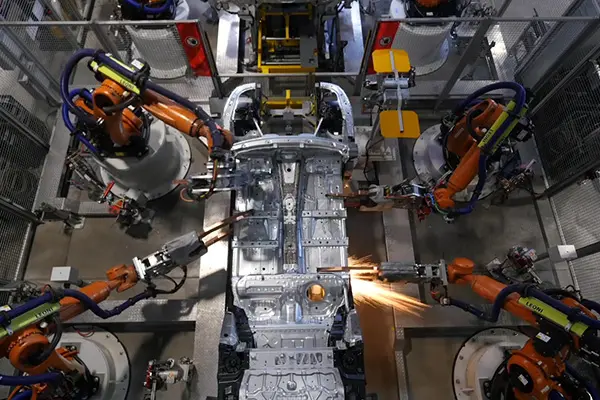

Body-in-white

World-Class Body Manufacturing

Magna can manufacture the complete range of bodies, covering everything from steel constructions to multi-material structural bodies and all-aluminum models. Our digitalized and flexible automation solutions ensure short integration times, even when making changes to existing body-in-white production processes. Our innovative use of state-of-the-art technology and an array of virtual tools, including simulations, help us integrate new products faster than ever before.

Multi-Material-Mix & Joining Technologies

The need to reduce global CO2 emissions is a mega-trend that will define our future. Cutting emissions will mean optimizing the way materials are used and processed for specific applications within automotive manufacturing. Achieving this aim at the same time as cutting costs will require new technologies for creating bonds between fundamentally dissimilar materials, such as between various metals (steel, aluminum, magnesium, etc.) and other materials (including hybrid materials or polymer reinforced metals), as well as between metals and surface coatings (such as Alodine on aluminum or zinc on steel).

Paint

High-Tech, High-Quality Finishing

Our paint shop is renowned for providing maximum flexibility, multi-material capability, and unbeatable quality. Our automated processes ensure your project will be delivered quickly and efficiently, whether it’s a small production run or a high-volume order. With Magna, anything is possible: from customized paint designs, to unique paint effects (including pearl coat, clear lacquer and matt finishes) to contrasting colors for roofs and doors, your wish is our command!

A Variety of Color Options

All our paint processes are designed to meet specific OEM requirements, and we are constantly working to find new solutions and develop our range of services and capabilities. Our aim is to provide the full range of color and finish variants regardless of volume, from lot size one tie colors, through prototypes and low-volumes, all the way through to mass production.

Assembly

Flexible Assembly Services from a World-Class Manufacturer

Alternative Production Technologies & Concepts

The automotive market is being driven by an ever more diverse range of factors, and demand for mobility is increasing rapidly. Increasingly complex products and processes are combining with ever shorter product, market, technology and innovation cycles to pose new challenges for the automotive industry. As a leading player in the automotive sector, we can help you open the door to new niches, shorter development times, efficient platform strategies, more modularization, new materials and innovative vehicle design.

Flexible Solutions

Our Range of Services

We help our customers improve their competitiveness and earnings potential. Our range of products covers flexible workflow and process planning, as well as the full range of optimization-related activities.

Tailored to Customer Needs

We work in partnership with our customers and draw on our extensive experience to develop suitable solutions. Our goals are flexible business models that are tailored to meet our customers' specific needs. We focus on a close cooperation with our customers regarding our fields of competence to ensure a successful project execution.

Stay connected with us!

One-Stop Shop

From concept to the road

The automotive market is disrupted by new technologies in the fields of alternative propulsion systems and autonomous driving. Various new players have entered the market with innovative vehicle concepts. Yet, launching a vehicle successfully in time is not an easy task. It requires a competent engineering and manufacturing team following proven processes in a high-quality production environment, including production plants, and a reliable supplier and distributor network.

Magna is the first and only automotive supplier that provides complete vehicle engineering and manufacturing in a one-stop shop. With our 120 years of automotive experience, we have established a global network of partners and suppliers. Magna has developed more than 40 complete vehicles and derivatives and produced about 4 million vehicles. By having reliability as our main concern, we were able to guarantee that every project so far has started on schedule.

Virtual development

Magna’s extensive experience in the field of virtual development is a key factor in our success. Our proven simulation methods and efficient development processes ensure a high degree of design maturity in the early phases of a project. The results: reduced development risk and cost. Virtual reality tools facilitate a global collaboration, ensure high-quality information in every project phase and enable decisions to be made quickly.

Flexible Manufacturing

Vehicle portfolio extension with minimal effort

Automakers faces challenges in the form of two major market requirements. The first of these is that strong competition, along with government regulations, are forcing them to develop and produce vehicles faster and at lower cost. As a solution to this, more and more are using global platform sharing. The second challenges is that customers are demanding a large variety of models to meet their need for customized solutions. Fulfilling both requirements results in a large amount of organizational effort and financial investment that is hardly profitable.

Magna has been supporting different OEMs and new entrants in this challenge. We can provide our customers with tailored solutions. Magna has so far been able to guarantee every single planned SOPs, which indicates our reliability and expertise when it comes to manufacturing complete vehicles.

We cover your back with flexible manufacturing

We can produce flexible quantities for a wide range of OEMs and new entrants through shared facilities and products. Magna does not only support automakers in the production of the vehicles, but also takes over the complete project management and coordination between the parties involved in the shared product.